50 Torbolton

50 Torbolton is a two-storey residential building that has been vacated for over 12 years due to ongoing flooding issues in the basements. It is situated on a charming site adjacent to Berry Creek with each unit having individual access to a garden and surrounding mature tree growth. The project includes a major upgrade to the building envelope, complete replacement of existing mechanical and electrical systems, and remediation and stabilization of ongoing water penetration issues.

The project addresses the city’s housing crisis by bringing back online seventeen single family units for Toronto Community Housing. Interwoven is a commitment to sustainability by reducing the building’s energy and carbon footprint, while providing significantly improved occupant comfort. The project is pursuing Passive House EnerPHit Certification.

In-Construction

Status

Principal-in-Charge: Kevin Stelzer

Project Architect: Krystyna Ng

Construction Administration Lead: Sean Cain

Structural, Mechanical, Electrial, Envelope, Energy Simulation: Morrison Hershfield

Code: LMDG

Project Team

Toronto Community Housing Corporation

Client

1,925 m2

Area of Work

Thermal Energy Demand Intensity: 23.4 kWh/m2

Proposed Energy Metrics

Total Energy Usage Intensity: 61.2 kWh/m2

Green House Gas Intensity: 3.3 kgs.CO2/m2

Onsite Renewables (PV): 43.2 kW

early design perspectives & sketches

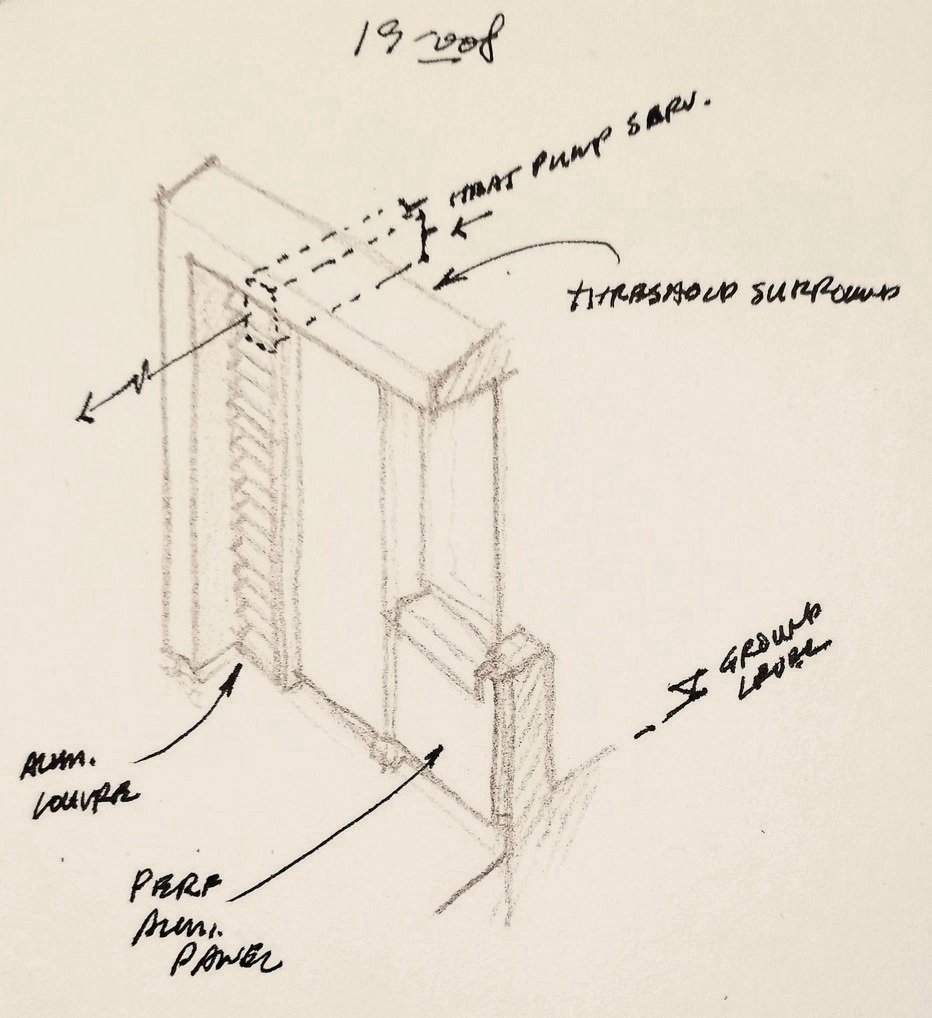

Passive House detail explorations

DESIGN ELEMENTS AND SITE INTEGRATION

50 Torbolton has a remarkable stature – very simple forms with a slight quirkiness – and is situated on a lovely site. The simplicity of the form is emphasized with a clean palette of materials and colours that expresses the purity of the existing volume. The form is highlighted with warm coloured design elements that signify entry to both the main corridor and individual units while connecting to the warm tones of the surrounding natural site.

The units have excellent access to daylight and the surrounding landscape. As such, the opportunity to connect residents to the wealth of surrounding nature was instilled through cascading wood steps and a thoughtful selection and placement of sedum cover, lavender beds, and pockets of tall ornamental grass that complement the mature tree growth already peppering the site. The seemingly casual site planning bellies the remarkable intimate outdoor spaces.

ENERGY OPTIMIZATION AND ENVELOPE

Energy optimization is a critical component to the creation of a durable and comfortable building – and a key element to Enform’s design process. As such, the project began with a comparative analysis between the thermal performance of SB-10 to Passive House EnerPHit standard. Both simulation options resulted in ultra-low energy consumption and supported the assertion that 50 Torbolton would be an excellent candidate for a deep energy retrofit. We note the exceptional TEDI of the Passive House option.

The specific methods applied to both approaches were to stabilize the existing exterior masonry with a durable rear draining EIFS, foam fill the rafter cavity of the roof and apply a conventional assembly above the current decking, and foam fill the rafter cavities on the underside of the first-floor slab. The combined approach of these methods provides a clearly defined thermal envelope and achieves exceptional airtightness on each building extremity. The major differences between SB-10 and Passive House EnerPHit is the depth of insulation provided, the types of windows and doors used (aluminum versus fiberglass), IGU performance, and the mechanical system used.

table comparing SB-10 and Passive House EnerPHit

MAIN AND INFILL WALL ASSEMBLY

In similar fashion to Enform’s other retrofit work, the main wall assembly (EW1A) for 50 Torbolton follows the approach of over cladding the existing masonry with a modular and light cladding system, in this case, a high-performance, rear draining EIFS. The infill wall assembly (EW1B) is used to reduce the existing window-to-wall ratio as well as provide new design proportions along the existing façade. The approach of these wall assemblies demonstrates an understanding and integration of existing building conditions, while representing our goal to maximize cost-effectiveness while delivering exceptionally high-performance buildings.

PURSUING PASSIVE HOUSE

An additional comparative analysis between Part 11: Minimum Code Requirements and Passive House EnerPHit standards were completed to present the more impressive analysis between energy performance of minimum code requirements versus energy performance of a Passive House EnerPHit retrofit. Following the comprehensive analysis of the capital cost versus the energy savings between SB-10 and Passive House EnerPHit, TCH decided to pursue the Passive House direction. The high-performance Passive House building envelope, along with robust detailing at each interface, allows for the selection of super low-energy mechanical and electrical systems.